The development was through research for NASA by a Scientist who was one of NASA’s chief engineers

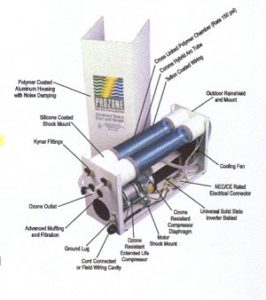

The Odor Destroyer is uniquely designed to maximize the performance of odor destruction. Built inside the main drive of the system is a special Space age Ozone Generating System to activ ate oxygen and transpose it into a blue gaseous allotrope of oxygen. This is accomplished by passing specially prepared oxygen through a VUV Ozone Generator; the Ozone is then injected into the Lift Station. Its mission is to breakdown gaseous contaminants into their basic compounds to eliminate undesirable odors. The unit is specifically built to control the output in relationship to the odor levels.

ate oxygen and transpose it into a blue gaseous allotrope of oxygen. This is accomplished by passing specially prepared oxygen through a VUV Ozone Generator; the Ozone is then injected into the Lift Station. Its mission is to breakdown gaseous contaminants into their basic compounds to eliminate undesirable odors. The unit is specifically built to control the output in relationship to the odor levels.

- Pure patented V.U.V. ozone to eliminate obnoxious hydrogen sulfide odors.

- Continuous low dosage with no harmful by products such as corrosive nitric acid or other contaminates.

- No expensive or complicated equipment with short life and costly repairs.

- Special Space age patented ozone generating system, developed to safely Maximize performance.

UNLIKE OTHER ODOR CONTROL DEVICES

The “Odor Destroyer” — Needs No–

- Needs no chemicals or biological agents.

- Needs no outside ion units.

- Needs no outside water hookups.

- Needs no excessive amount of ground space.

- Needs no frequent monitoring, servicing or frequently scheduled maintenance.

The “Odor Destroyer” — Does–

- Does process stable long life pure non corrosive ozone to maximize the effectiveness of Oxidation.

- Does use a precisely measured amount of ozone to immediately destroy odor.

- Does have a negligible impact on materials within the Lift Station.

- Does not continue oxidizing to the detriment of the fixture. Additionally most Ozone will be consumed in interactions with the off-gassing from the sewage.

- Does prevent bio build-up and greatly reduces labor for lift station maintenance.

- Does not require excessive space, energy or cost to operate.

THE FACTS

Ozone and Corrosion

- Ozone is not a corrosive agent – it is an oxidant

- Ozone will oxidize a surface and form a patina which limits further oxidation

- Ozone’s super-passivated oxidized surface has a higher resistance to corrosion.

Ozone Generating Methods

1. Irradiating the air with ultraviolet light at 185 nm .

2. High voltage electrical field (Corona Discharge).

The difference in the manner in which ozone is created is important to understand. The ultraviolet method of generation only produces pure ozone while the corona discharge ozone generation process creates ozone, nitrous oxides, and nitric acid. Nitrogen oxide compounds form nitric acid, which is extremely corrosive.

The amount of energy in the ultraviolet ozone generating lamps is enough to create ozone, but too low to create nitrous compounds.

Summary of Ozone Production

- Ultraviolet ozone generators produce only pure ozone.

- All corona discharge ozone generators produce nitrogen oxides, nitric and nitrous acids unless pure oxygen is used as the feed gas

- Corona discharge units which use oxygen concentrators still produce nitrous oxides.

Ozone in Lift Stations

Ozone concentrations in a lift station environment are expected to have a negligible impact on  materials.

materials.

Doors and Other Bulk Metal Type Fixtures: No impact expected. Aside from the fact that environmental factors will have a much more severe impact-ozone will interact as listed above. If any oxidation occurs, it will self-limit. Ozone will not continue oxidizing to the detriment of the fixture. Additionally, most ozone will be consumed in interactions with the off-gassing from the sewage.

Specifications

ARC Life (Nominal): 20,000 hours

Compressor Life (Nominal): 40,000 hours

Operating Temperature: -25° F to 140° F

Footprint

22” wide, 30” deep & 70” tall

Electrical:

The system will operate on 110VAC/60Hz System. Connector will be provided as specified. 220/50 and 220/60 units are available